Hazardous Area Electrical Services

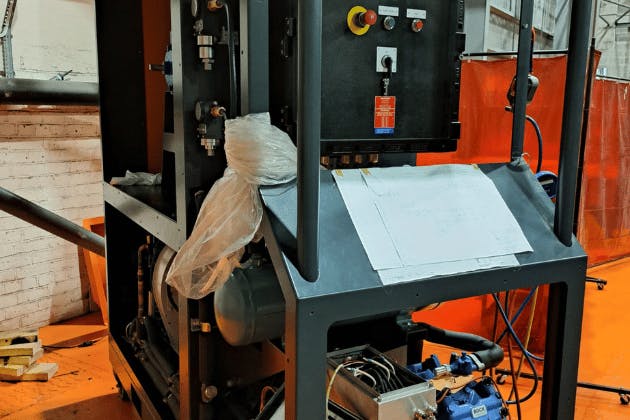

In the high-stakes environment of oil and gas operations, proper hazardous area installations and inspections aren't just regulatory requirements—they're critical safeguards protecting lives and assets. At Bell Electrical, we deliver specialist Compex Ex01-04 certified services for hazardous area installations and inspections across Aberdeen and Aberdeenshire.

As NIC-EIC approved contractors with extensive experience in both onshore and offshore environments, we understand the complex requirements of working in potentially explosive atmospheres. We ensure every installation and inspection meets the stringent standards set by IEC, NFPA, and UK regulations.

Hazardous Area Electrical Installations & Inspections

Hazardous areas are locations where flammable or combustible substances create potentially explosive atmospheres. In oil and gas facilities, these substances typically include gases, vapours, mists, and dusts that, when mixed with air, can ignite under specific conditions.

Common hazardous areas in the oil and gas sector include:

- Storage facilities for flammable liquids

- Process areas with volatile hydrocarbons

- Paint spray booths

- Battery charging rooms

- Fuel dispensing locations

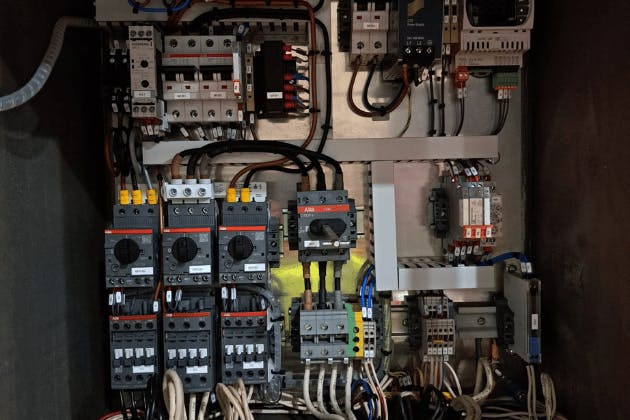

Bell Electrical provides comprehensive installation services that include:

- Installation of explosion-proof enclosures and junction boxes

- Implementation of intrinsically safe systems

- Cable gland selection and installation

- Earthing and bonding systems

- Installation of monitoring and control equipment

Our inspection services ensure ongoing compliance and safety through:

- Visual inspections of equipment conditions

- Detailed checks of protection concepts

- Cable entry system verification

- Earth continuity testing

- Insulation resistance measurements

- Documentation review and updates

Classification of Hazardous Areas

Hazardous areas are categorised into specific zones based on the frequency and duration of explosive atmosphere occurrence:

Zone 0

Areas where explosive gas atmospheres are present continuously or for long periods. These zones require the highest level of protection and specialised equipment.

Zone 1

Areas where explosive gas atmospheres are likely to occur during normal operations. Common in areas surrounding Zone 0 locations and near venting devices.

Zone 2

Areas where explosive gas atmospheres are unlikely during normal operations and, if they occur, persist only for short periods. Often serves as a buffer between Zone 1 and non-hazardous areas.

Compex Ex01-04 Certification

Bell Electrical holds Compex Ex01-04 certification, the gold standard for working in hazardous areas. This certification encompasses:

- Ex01: Preparation and installation of Ex equipment

- Ex02: Inspection and maintenance of Ex equipment

- Ex03: Installation and inspection of Ex equipment in protection concept 'Ex i'

- Ex04: Inspection and maintenance of electrical installations in hazardous areas

Training and Compliance

Our commitment to safety extends beyond certification. We maintain continuous training programmes covering:

- Latest IEC standards updates

- Equipment-specific training

- Emergency response procedures

- Risk assessment techniques

For expert hazardous area installations and inspections across Aberdeenshire, contact Bell Electrical on 07815612849. Our Compex-certified technicians ensure your facility's safety and compliance.

FAQs

Expert Hazardous Area Installations & Inspections

Ensure your facility's safety and compliance with our Compex Ex01-04 certified specialists. Serving Aberdeenshire's industrial sector with precision and expertise.